Fassa Bortolo production plants have more than quadrupled since 2000, spreading across Italy, Europe and beyond.

Establishing so many plants is a bold choice, but it is also a practical demonstration of how important it is for Fassa Bortolo to offer a timely and efficient service to our customers, coupled with the high quality products that result from our constant focus on technological innovation. Being present in the territory, being close – not just metaphorically – to the needs of those working in the building industry, is key to the success of the Fassa system.

Our business lines dedicated to lime and plasterboard operate under a certified quality management system, ensuring controlled processes, reliable products, and a constant commitment to continuous improvement. A tangible guarantee for customers, designers, and industry professionals.

The scope of the certificates specifically covers:

- Design and production of aerial and hydraulic limes: Spresiano (TV) headquarters and plant, Montichiari (BS), Ceraino di Dolcè (VR), Villaga (VI) plants

- Design and development of building products based on hydraulic, aerial, gypsum, and organic binders; execution of chemical-physical and technological analyses (Spresiano – TV)

- Design and development of plasterboard sheets and building products based on hydraulic, aerial, gypsum, and organic binders; execution of chemical-physical and technological analyses (Spresiano – TV, Montichiari – BS, Calliano – AT)

The issuance of the certificate is not only based on the compliance of the plants or the production process with the relevant standard, but also on all company processes and functions that contribute to the specific business areas.

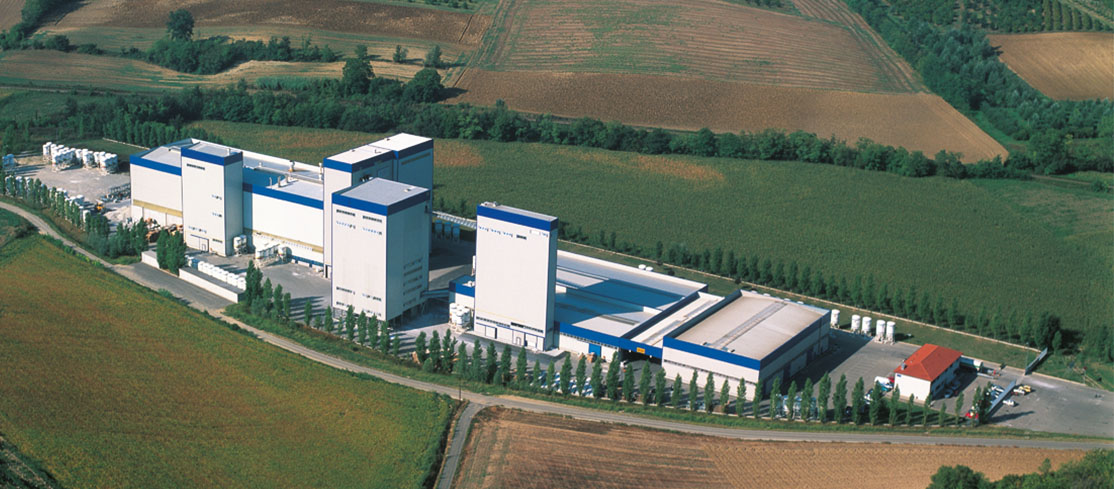

Spresiano (TV) – 1981

Tradition and innovation coexist perfectly in the production plant in Spresiano. As the first plant built by Fassa Bortolo, it is located in an area closely linked to the history of the Fassa family. Since 1981, the Spresiano site has been turning out high-quality premixed products, and today there are two technologically-advanced, highly-automated plants for the production of lime and premixed products, with a daily capacity of 2000 tonnes.

Artena (RM) – 1988

A factory that marked a milestone in the history of Fassa’s evolution, since it is the second with a completely automated system for the production of premixed products, both loose and in sacks. It has a production capacity of 1,500 tonnes per day.

Mazzano (BS) – 1991

From extraction of raw materials to finished products. With a daily production capacity of 1,500 tonnes of premixed plasters and renders, it offers the highest quality on the Lombardy market. Ravenna – 2000 Maximum production flexibility thanks to the double mixing line. The unique location, with direct access to the sea, makes this plant a starting point for new commercial developments.

Ravenna – 2000

Maximum production flexibility thanks to the double mixing line. The unique location, with direct access to the sea, makes this plant a starting point for new commercial developments.

Moncalvo (AT) – 2001

Fassa’s first plant for gypsum-based products, with a complete production cycle: from underground extraction to firing and refining in rotary kilns, with a daily production of 800 tonnes.

Bagnasco (CN) – 2002

With a quarry for extraction with partially-underground crushing and processing, the facility boasts a production capacity of 1,500 tonnes per day and advanced dust abatement systems, which make it a reference point for the north-west.

Molazzana (LU) – 2002

A plant equipped with all the most innovative technologies, tested at Fassa’s previous plants. Supported by the Altopascio warehouse, it ensures prompt deliveries and services in Tuscany and the Levante Ligure area.

Popoli (PE) – 2003

The factory has a double mixing line with processing of raw material from the nearby quarry owned by the company. Its strategic position in the heart of Abruzzo makes it the point of reference for central-eastern Italy.

Batalha (Portogallo) – 2004

Located between Portugal’s two main cities, Lisbon and Porto, Fassa’s first production plant abroad. The site offers all the entire range of products directly to the Portuguese market.

Sala al Barro (LC) – 2005

A state-of-the-art facility serving the local territory of Lombardy and the northern provinces of Piedmont up to Switzerland, with a double mixing line and computerised control systems. It blends perfectly with the local landscape and is designed to reduce noise pollution.

Montichiari (BS) – 2006

A plant entirely dedicated to the production of lump lime, hydrated lime and aerated calcium oxide. Equipped with two modern Maerz parallel flow regenerative shaft kilns, it has a production capacity of 1,000 tonnes per day. A facility with reduced environmental impact that meets the strictest European standards.

Bitonto (BA) – 2008

An area of over 40,000 square meters in the heart of southern Italy, in a strategic position to serve Apulia, Basilicata, Calabria, Campania and Sicily with the entire range of Fassa products.

Calliano (AT) – 2009

The first Fassa Bortolo plant for the construction of plasterboard. Technologically advanced, with a constantly-monitored, continuous-cycle production process.

Ceraino di Dolcé (VR) – 2017

This plant was built in 1998 for the production of premixed building products, lump lime, hydrated lime and aerated calcium oxide. The plant was bought by the Fass Group in 2017 and, in 2019, work was started to upgrade it, which was completed in 2021.

Villaga (VI) – 2017

Historic factory founded in 1897 with the construction of a kiln for the production of hydraulic lime. Over the years there have been improvements in production plants and technological innovation which enables production of natural hydraulic lime (NHL) with high technical performance.

Calce Barattoni S.p.A. Schio (VI) – 2017

Built in 2000 and in 2013 converted into a double-shaft regenerative kiln for dolomite lime production. Annual production capacity currently exceeds 100,000 tonnes.

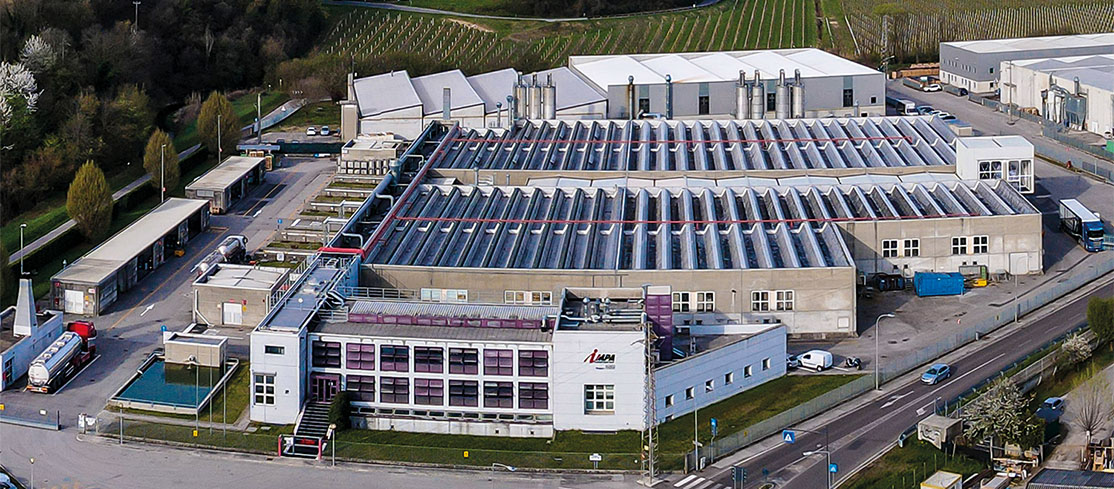

IMPA S.p.A. San Pietro di Feletto (TV) – 2017

An important plant that is certified in accordance with the ISO 14001 guidelines and produces paints and coatings. Here products of excellence are developed for construction, industry and vehicle bodywork.

Antas (Spagna) – 2018

YESOS ESCAYOLA Y DERIVADOS SA is a Spanish company with 35 years of experience in the building materials sector. A leader in the production of gypsum, gypsum and cement plasters and renders, false ceilings, cement adhesives, dry and pre-mixed mortars, with its 25,000 m2 building it is one of the most important production sites on the entire Iberian peninsula.

Matozinhos (Brasile) – 2021

Fassa opened a new production plant in Brazil, located in a strategic area of Belo Horizonte in the state of Minas Gerais. The new production site covers a total of 50,000 m2, with a large part dedicated to production infrastructure. All the raw material is obtained from local quarries and transformed into products ready for distribution. The plant produces around 300,000 tonnes of technical and traditional premixed products per year.